Golfers love the making of custom golf bags to stand out on the course and express their style. While customizing your clubs or shoes is relatively straightforward, designing a unique golf bag from the ground up can feel overwhelming without guidance.

This article explores the entire process of conceptualizing and creating a fully customized golf bag – from selecting premium materials and exploring vibrant color options to choosing specialized engraving or embroidery treatments to make your bag a true one-of-a-kind asset on the rack. We’ll break down each step of the process so you understand the possibilities and can confidently discuss your vision with a master bag designer.

By the time you finish reading, you’ll be prepared to collaborate on bringing your dream custom golf bag to life while gaining insight into ensuring quality control standards are met throughout manufacturing. Let’s get started with exploring material choices! How to use Hybrid Golf Clubs appropriately

The Making of Custom Golf Bags

Creating custom golf bags involves a combination of design, material selection, and manufacturing processes. But, before looking into these factors, let’s put a cursory glance at Custom Golf Bags

What are Custom Golf Bags

Custom golf bags are the bags that golfers design according to their needs and style preferences. The golfer adds some color or touches the logo, etc. Sometimes, these custom golf bags are also used for business promotions.

Design Consultation and Conceptualization

Initial Consultation:

The first step in the design consultation phase is a conversation with experts in the field of golf bag customization. This consultation is meant to discuss what you are looking for, preferences, and expectations. The expert will work closely with you, understanding your vision and translating it into a unique and personalized design.

During this consultation, discussing the materials, style, pockets, color, dimensions, and other available customization options is essential.

Conceptualization:

Once the initial consultation is done, the experts begin the process of conceptualization. This customization stage involves creating draft designs and bringing your vision to life. During this stage, you can choose from various layout options, graphic placements, and design elements like color, contrast, and typography. You can work with the experts to adjust, refine, or improve the ideas until a final design is agreed upon.

Prototyping:

After conceptualization and final design, here comes the prototyping stage. This stage is crucial in customizing a golf bag according to your needs. It allows you to have a prototype of the design before its production. With the help of advanced modeling and computer-aided design (CAD) tools, you can analyze the design from all angles. If you need specific changes, you can also do that. You can also evaluate the fabric’s quality, pockets, drainage, and other features that you chose before.

Production:

Once you have approved the final design, the customization comes full circle with the production stage. Here, the experts use high-quality materials to create a golf bag representing your style and preferences. Before the delivery of the final product, it is tested. This testing has been done to ensure that it meets the standards.

Material selection

Leather:

Leather is a classic material choice for golf bags. It is durable, stylish, and will stand the test of time. However, it is also one of the most expensive materials to use. However, leather is an excellent choice for those who are traditionalists. And they want a bag that will stay with them for years.

Nylon:

Nylon is an affordable and lightweight option for golf bag customization. It is also water-resistant. Further, it required low maintenance. However, it is less durable than leather. Also, it may have less visual appeal.

Canvas:

Canvas is a popular material choice for golf bags. This popularity is because it is both durable and affordable. It is also weather-resistant and easily cleanable. Canvas is an excellent choice for those who want a bag that can withstand the elements.

Denim:

Denim is a unique material choice. It can add a touch of personality to your golf bag. It is easy to customize with embroidery or appliqué. However, denim may not be as durable as other materials. Also, it may not provide as much protection for your clubs.

Microfiber:

Microfiber is a synthetic material. It is both lightweight and durable. It is also water-resistant and easy to clean. Microfiber is an excellent choice for those who want a bag that is easy to carry.

Color and pattern options

Classic Colors:

If you prefer a traditional look, you can opt for classic colors like black, brown, grey, or navy blue. These colors match any outfit and make your bag look sleek and professional.

Moreover, you can add a touch of elegance to your customized golf bag by opting for tone-on-tone embroidery or subtle prints.

Bold Colors:

For those who want to make a statement, bold colors such as bright red, orange, yellow, green, or blue are great options. These colors can add a pop of color to your golf bag, giving it a modern and edgy look. You can also mix and match these colors or go for a multi-colored bag with more than one bold color.

Stripes and Checks:

If you love patterns, you can opt for stripes or checks that add a classic and preppy vibe to your golf bag. You can choose from horizontal or vertical lines and different sizes of stuff, such as gingham, houndstooth, or tartan.

Custom Design:

If you want to add a personal touch to your golf bag, you can create a custom design that reflects your personality. For example, you can add your favorite sports team logo, company logo, or artwork. Moreover, you can choose the color palette that matches your design and the embroidery thread that enhances the color scheme.

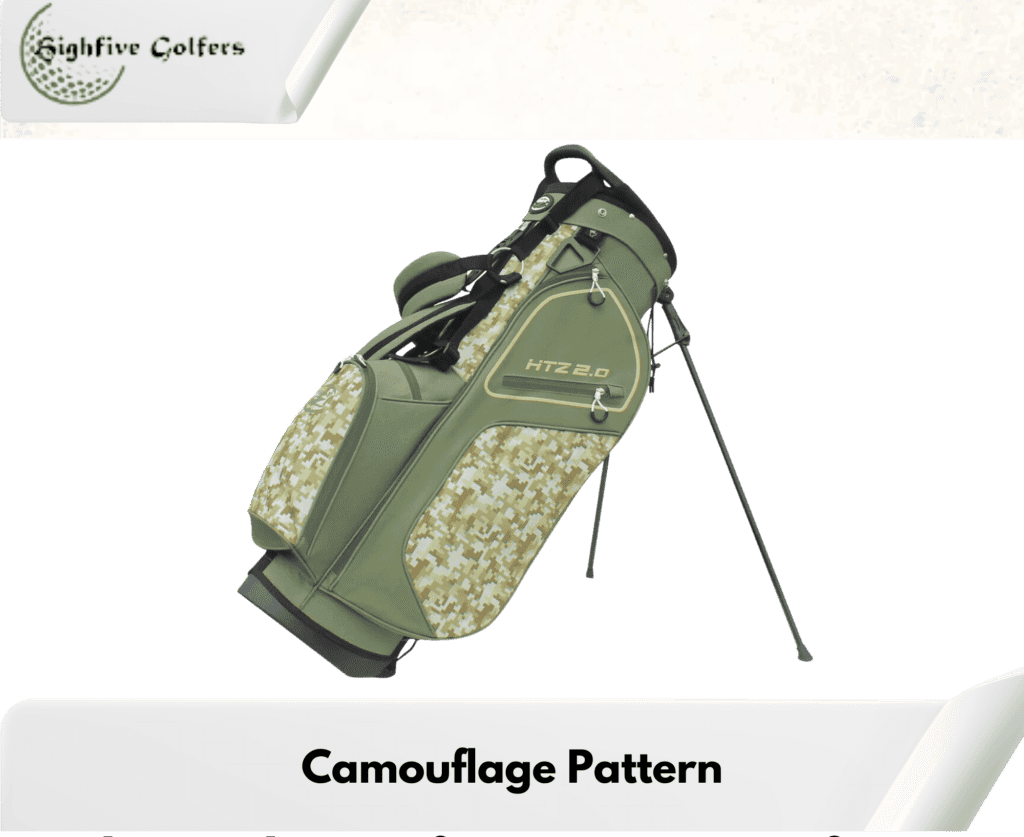

Camouflage Pattern:

Camouflage is a popular pattern that always stays in style. If you want to add a rocky and manly look to your custom golf bag, choose from different camouflage patterns such as woodland, desert, or digital camo. Moreover, you can add a personal touch to the design by selecting the embroidery thread color matching the pattern’s color.

Customization techniques

Embroidery

Embroidery is a popular customization technique to add your name or any other custom message to your golf bag. It’s an excellent way to personalize your golf bag without being too flashy. Embroidery can be quickly done on various fabrics, including nylon, polyester, and canvas. You can choose the embroidery’s font type, size, and color, and it can be positioned anywhere on your golf bag.

Custom Pockets

If you’ve been playing golf for a while, you know that a well-organized golf bag is the key to a great game. Custom pockets allow you to customize your bag according to your needs. You can add pockets for tees, golf balls, rangefinders, cigars, or any other requirement. This customization technique helps you keep your golfing accessories organized, within reach, and easily accessible.

Personalized belt

The strap is an essential part of the golf bag, as it bears the bag’s weight on your shoulder. That’s why it’s crucial to use a comfortable and durable strap. Customization allows you to choose the strap’s color, width, thickness, material, and padding. That makes sure it’s not only comfortable but looks good too.

Painting

Painting is another way to add some personality to your golf bag. You can paint your bag in a specific color or pattern to express your individuality and make your bag stand out. Painting also lets you quickly identify your bag on a crowded golf course.

Monogramming

Monogramming is another popular customization technique used in golf bags. Monogramming lets you add your golf bag’s initials, name, or logo. It’s a great way to add a personal touch to your bag without being too bold.

Manufacturing Process

Pattern creation and cutting:

The first step in creating a custom golf bag is to decode the design into a pattern template. This pattern guides the cutting process and ensures uniformity in the bag’s size and features. Once the way is finalized, leather, nylon, or polyester are precisely cut according to the pattern.

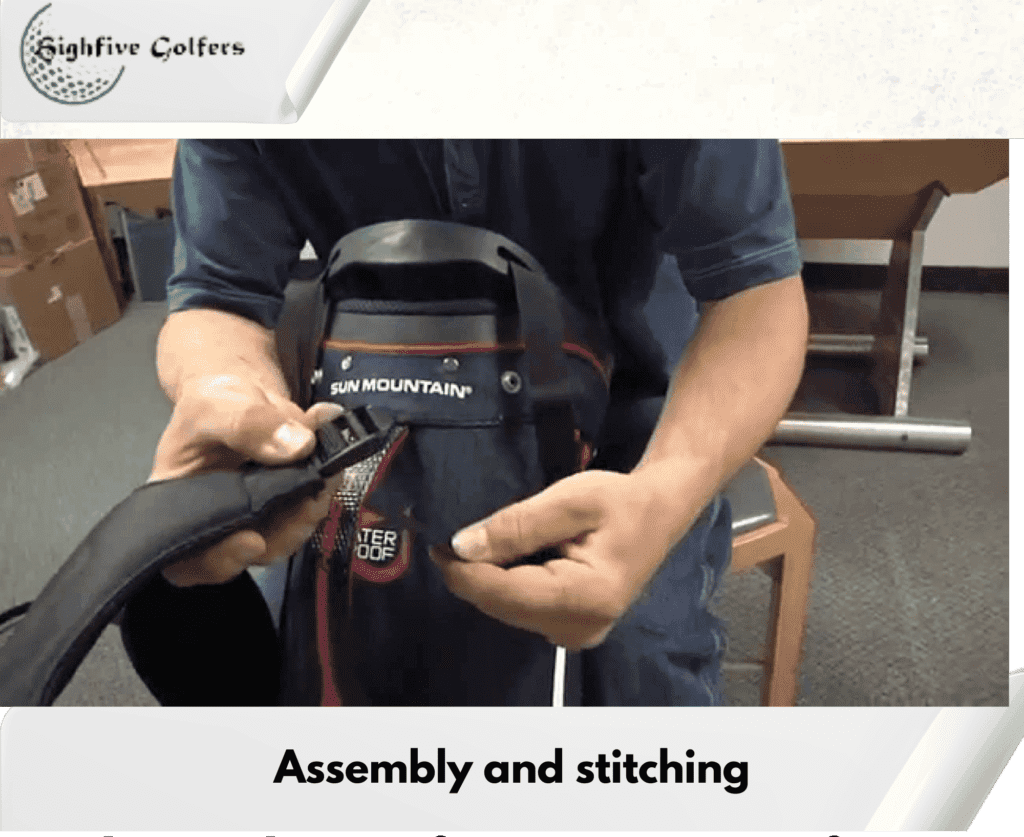

Assembly and stitching:

After the materials are cut, the bag’s components are brought together. These components usually include the main body, pockets, straps, and zippers. The assembly process requires attention to detail to ensure all the pieces line up correctly and any custom features are accurately incorporated. Stitching is done with industrial machines that can work with heavy-duty materials. Quality stitching ensures the bag’s durability and aesthetic appeal.

Addition of custom features:

One of the main reasons for customizing a golf bag is to add specialized pockets, dividers, or other accessories specific to a golfer’s needs. This customization can include separate club compartments, a cooler pocket, or a built-in GPS device holder. The manufacturer works closely with the golfer to ensure these custom features align with their needs and preferences. These features are carefully integrated into the bag’s design, and it’s essential to ensure they don’t interfere with the bag’s balance or functionality.

Testing and quality control:

Before a custom golf bag is released to the golfer, it must undergo tests and quality control measures. These include stress testing, water resistance testing, and general wear and tear testing. The manufacturer also conducts visual inspections to ensure the bag has a clean finish without loose threads or glue marks. Any defects are corrected before the pack is released to the customer.

Quality control

Inspection of the Final Product

The final product should be inspected thoroughly to produce a high-quality custom golf bag. This inspection checks for flaws or imperfections that could affect the bag’s appearance or functionality. Any visible defects, such as loose stitches, discoloration, or incorrect embroidery, should be addressed and fixed before the bag is shipped to the customer. Additionally, the inspection should verify that the custom design is accurately implemented, from the color scheme to the logo placement. This audit will ensure that the customer receives what they ordered.

Testing Functionality and Durability

Another critical aspect of quality control for custom golf bags is testing for functionality and durability. This testing ensures that zippers, straps, and compartments function seamlessly without resistance or jamming. Also, trying the overall build quality to guarantee that the bag can withstand regular use and weather elements

Meeting Industry Standards

Besides the inspection and testing process, custom golf bags should also meet industry standards and regulations. It means complying with the rules set forth by the relevant authorities, such as safety standards for materials used in golf bag construction. Meeting industry standards ensures the customer’s safety, satisfaction, and trust in the brand. It also shows that the company is committed to providing quality products that adhere to the regulations.

Customer Feedback

Customer feedback is the last key aspect of quality control for custom golf bags. After the customer has received and used their bag, they should be allowed to provide feedback on their experience. This feedback helps the manufacturer identify areas needing improvement and make adjustments before producing the next batch of custom bags. It also enables the brand to remember customer trends and preferences, informing the design process and improving product offerings.

Conclusion:

In a nutshell, from start to finish, producing a custom golf bag requires attention to detail. It all starts with a design consultation and conceptualization stage, which paves the way for material selection, color and pattern options, customization techniques, and, ultimately, a successful manufacturing process.

FAQs:

Why should I get a custom golf bag?

A custom golf bag offers many benefits, such as:

- Personalized design tailored to your needs and preferences

- Better organization and accessibility of your golf equipment

- Enhanced comfort and ease of carrying

- The potential for improved performance on the course

How do I start the process of getting a custom golf bag?

To get a custom golf bag, you can reach out to a golf bag manufacturer or designer to discuss your needs and preferences. They will work with you to create a design that fits your specifications.

How long does it take to make a custom golf bag?

The time it takes to make a custom golf bag varies depending on the manufacturer and the complexity of the design. On average, it can take anywhere from 4-8 weeks to produce a custom golf bag.

How much does a custom golf bag cost?

The cost of a custom golf bag can vary greatly depending on the materials, design, and features chosen. A customized golf bag can range from $200 to $1000.

Can I personalize my custom golf bag with my name or logo?

Most golf bag manufacturers offer personalization options such as embroidery or printing names and logos on custom bags. This personalization adds a unique touch and can serve as an identification feature on the course.

3 Comments

Thank you for this informative post. It was very enlightening and offered valuable knowledge.

I’m thoroughly captivated with your deep insights and stellar ability to convey information. Your depth of knowledge is evident in each paragraph. It’s obvious that you invest a great deal of effort into understanding your topics, and this effort does not go unnoticed. Thank you for sharing such detailed information. Keep up the great work!

I’m truly impressed with your deep insights and stellar ability to convey information. The knowledge you share clearly stands out in every sentence. It’s clear that you invest a great deal of effort into understanding your topics, and this effort pays off. Thanks for providing such detailed information.